Each special demand placed on a certain product requires an appropriate solution. We will show you the

possibilities afforded by high-performing,

technical fabrics for your specific field of application. The following presents some of the

successfully established end products that we have developed

in collaboration with our customers:

It was finally possible to walk on water for 16 days between June 18 and July 3, 2016. Following

intensive preparations, the company SETEX Textil GmbH

produced approximately 103,000 m2 of polyamide fabric of approximately 317 g/m2 on

a rapier weaving machine for this project.

The fabric was processed into a gigantic, floating walkway on Italy’s Lake Iseo. During this period,

visitors and residents were able to walk on water

for three kilometers from Sulzano to Monte Isola, as well as to San Paolo Island.

The fact that we were entrusted with this excellent art project makes us very proud.

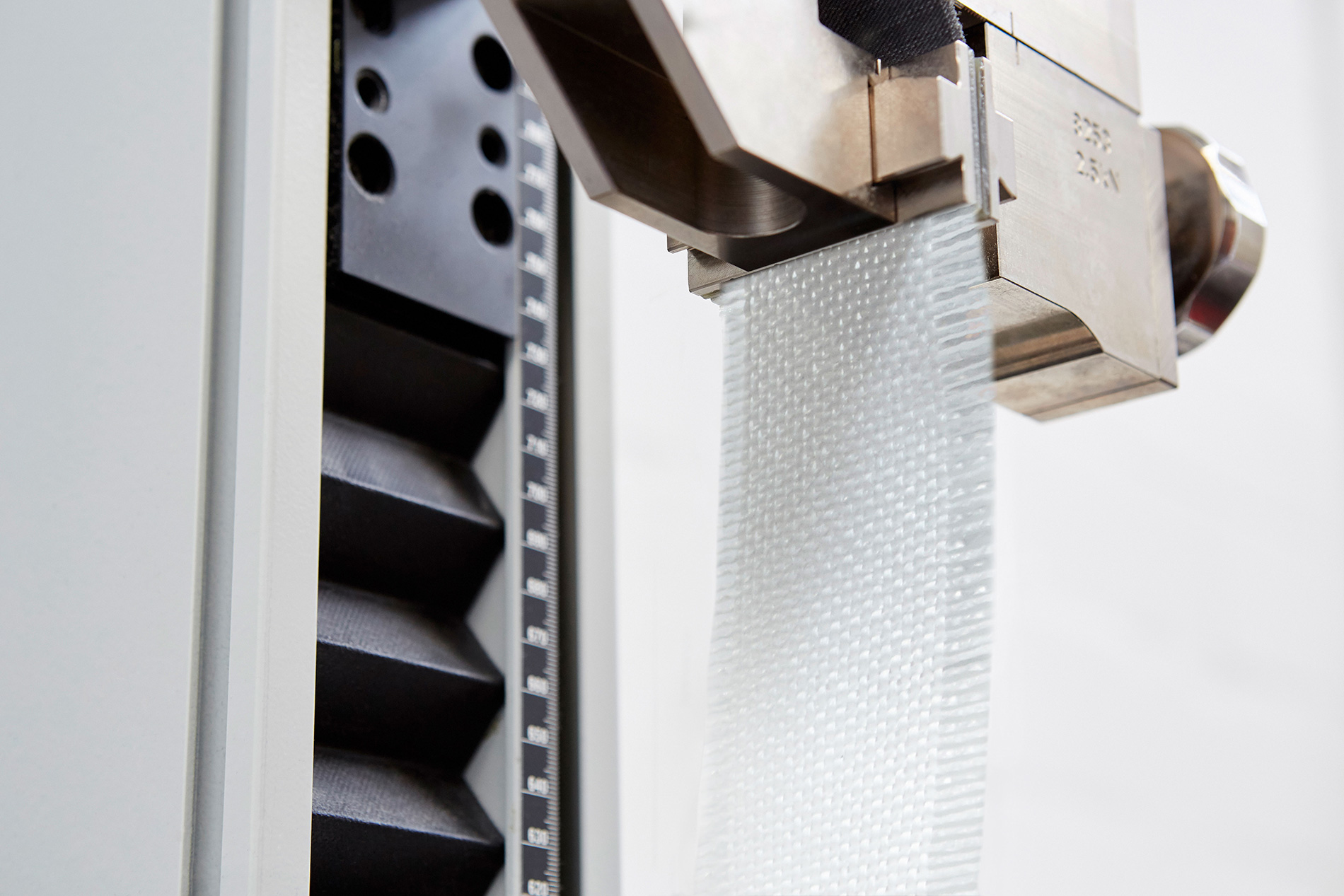

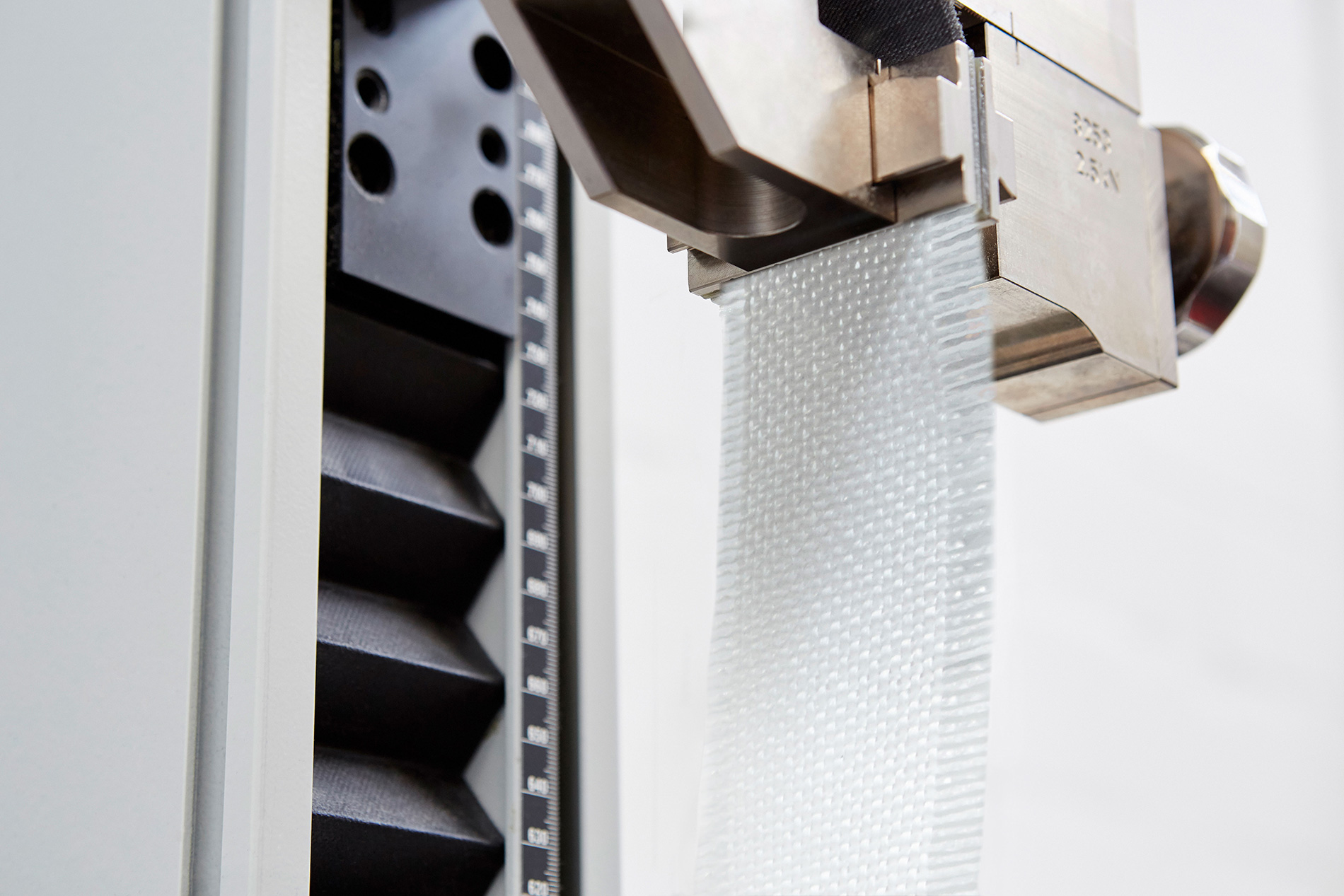

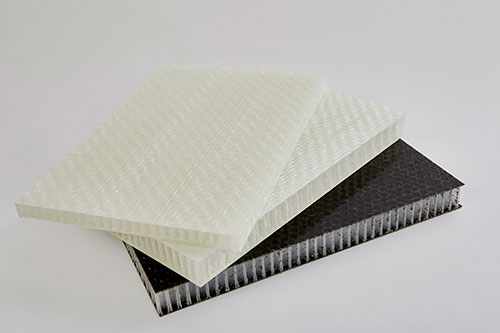

TAPEFABRIC – The latest brand product from SETEX Textil GmbH is an innovative

thermoplastic material with glass content and a polypropylene matrix.

This unique fabric is the future of lightweight construction, and it offers some clear benefits, such as

short cycle times during processing and extreme strength

in spite of its light weight. The finished end product exhibits good “crash behavior,” as it barely

chips! TAPEFABRIC already protects the environment

during processing, as the waste created can be reused. Talk to us and we will be happy to introduce you

to TAPEFABRIC personally!

Advantages:

| Weight | 820 g/m2 |

| Glass | 70% |

| PP | 30% |

| Tensile force L (EN-ISO 13934-1) | 22 KN |

| Tensile force Q (N/10 cm) | 22 KN |

| Width | Max. 1,80 m |

| Color | Natural or black |

| Presentation | Available in a roll or in pieces |

| Edge | Can be cut thermally or by turning |

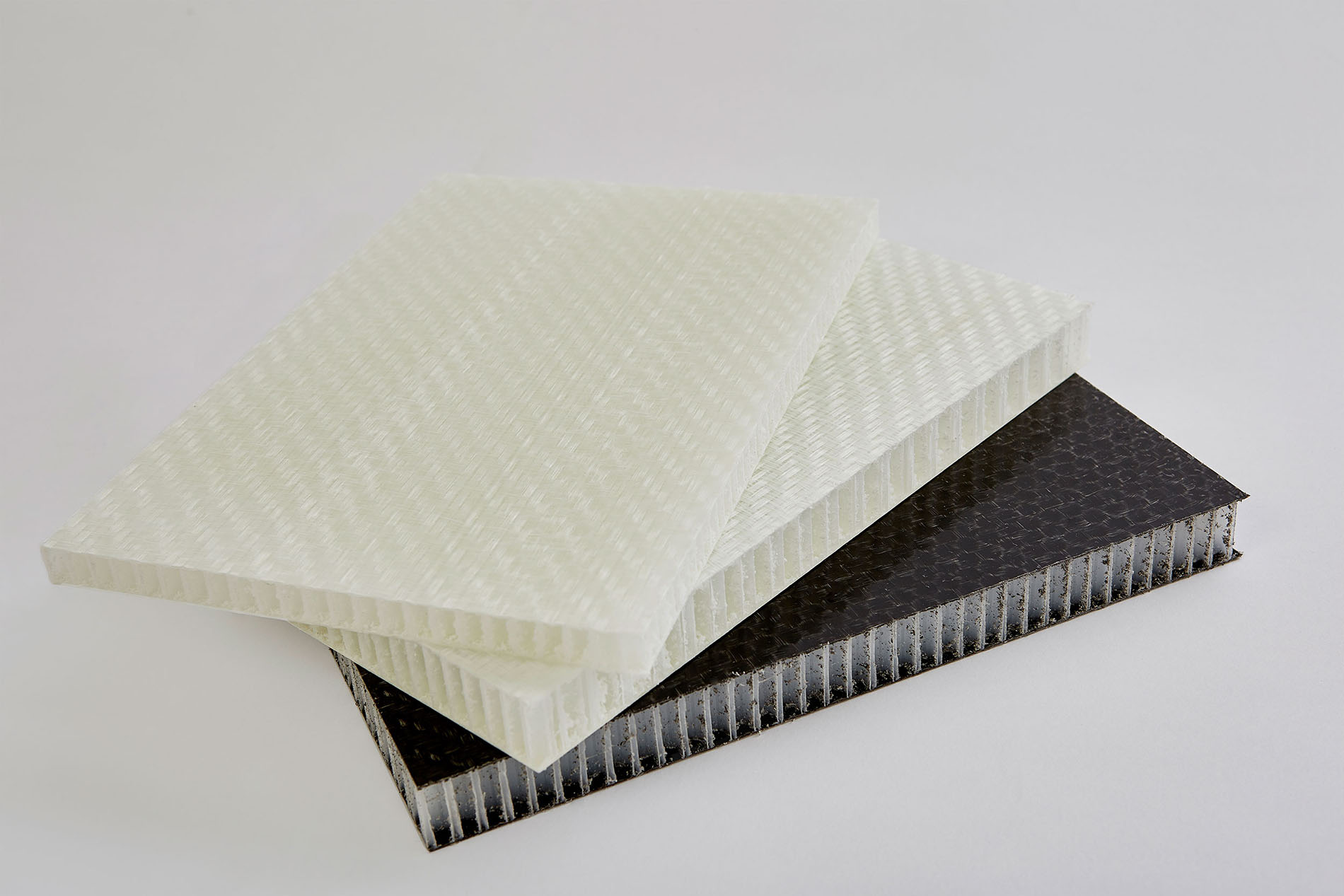

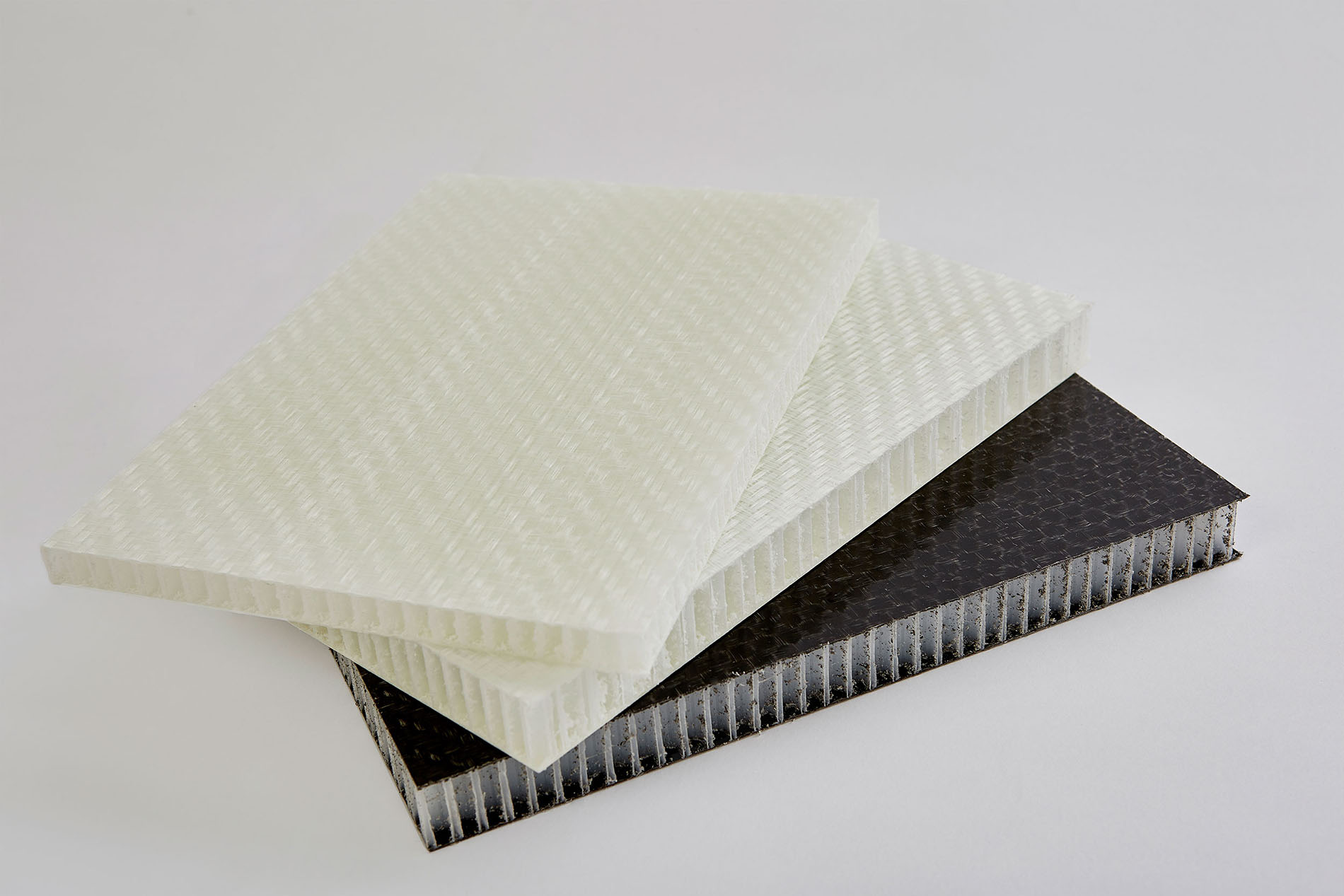

Composites and lightweight construction solutions made from glass, basalt, aramid fiber or hybrids

The following presents some of the successfully established end products that we have developed in

collaboration with our customers:

It goes without saying that we are also happy to help you to develop customized solutions, for which our specialists and the corresponding machinery is available. Get in contact with us and we will show you new, creative textile paths.